Homedics Heated Wellness Products

Creating a consistent design identity for a mismatched product line

Challenged with a patchwork array of heating products in their lineup, Homedics was looking to infuse uniformity into the collection while maintaining cost-effectiveness.

Inspiration

With some rough ideas in mind, I looked to the fashion and furniture industries for inspiration of colours and textile treatments, as well as soft and modern forms for the controllers.

Design Identity

The existing products in the lineup lacked any cohesive design elements to tie them together. To address this, we developed a shareable design language. This included a printed pattern based on the company logo for low-pile fabrics, a heat-pressed faux quilting pattern for fleece and plush fabrics, and a muted neutral colour palette.

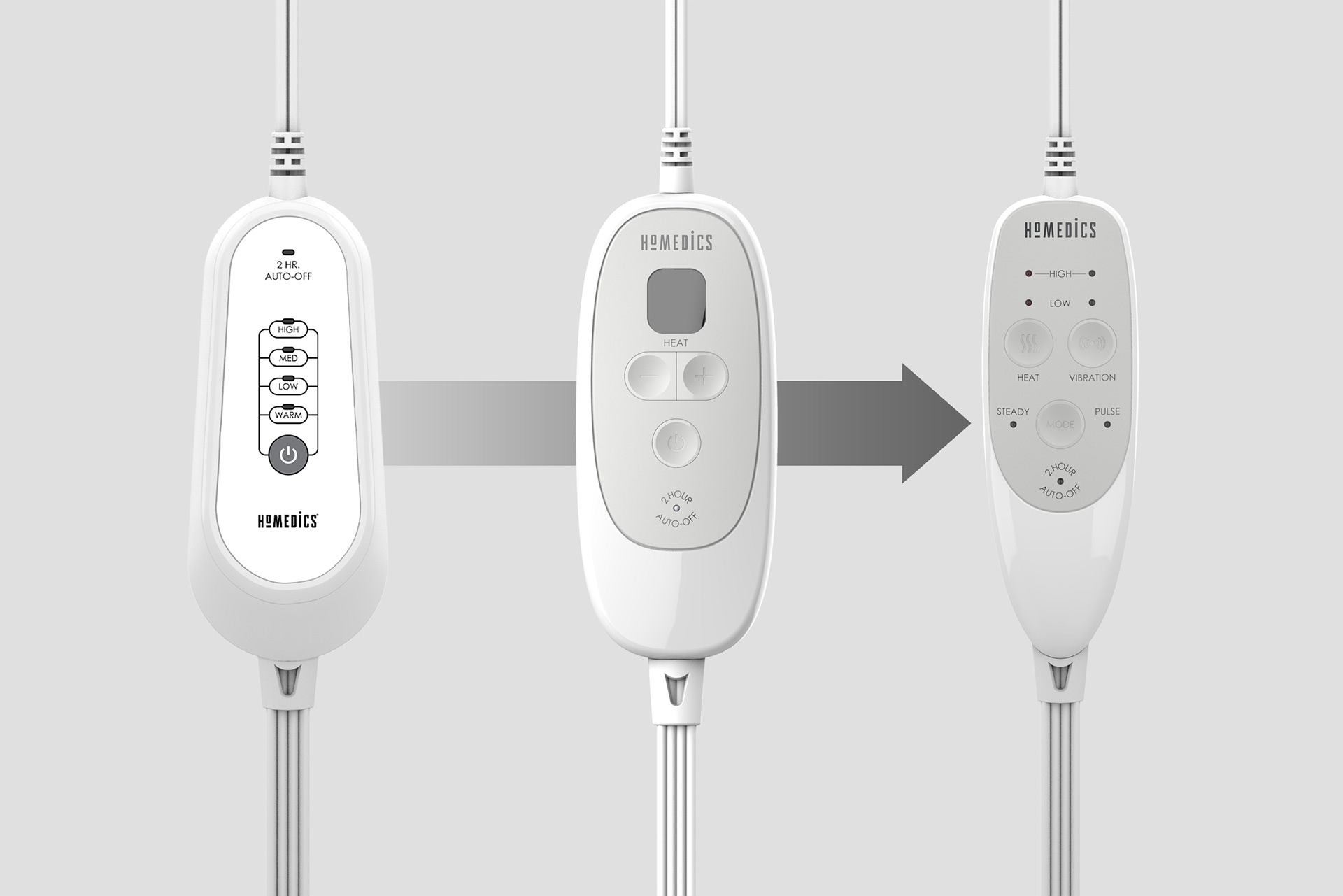

Standardized Controller Design

To streamline costs and enhance consistency, I developed a versatile controller design that allowed multiple products to share the same tooling. An interchangeable faceplate was used to accommodate each item’s unique functions. I went through several iterations of the overall form and sizing, incorporating feedback from the client and engineering teams. While the original design used a printed membrane control surface commonly used by Homedics, I successfully pitched the value of elevating the final design with a molded control surface and buttons.

Project Management

The original brief included 25+ potential SKUs for the new lineup, so a high degree of organization was required to ensure nothing slipped through the cracks. On top of developing the design identity, I managed it's application to all of the new and existing products, from concept through to production. This included preparing CMFG assets and documents, communicating with the factory, and reviewing samples to ensure the the final production versions followed my design intent.

Result

The project culminated in the successful launch of over 16 new and updated product SKUs, all featuring consistent design elements that unified the product line. The use of shared materials and controller tooling significantly reduced production costs, thus increasing profitability.

Product photography: www.homedics.com